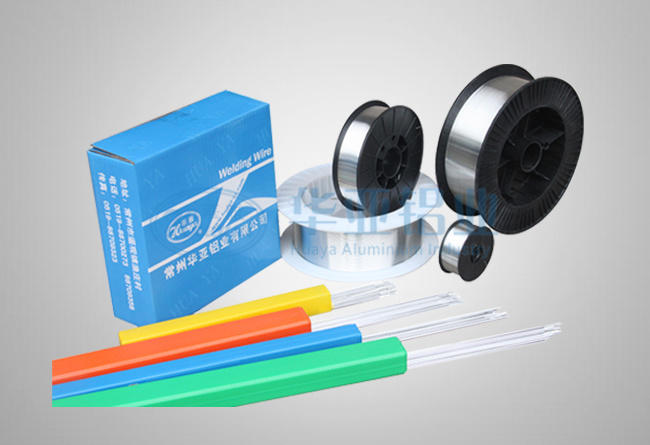

Aluminum & Aluminum Alloy Welding Wire

IA1050/A1100: Pure aluminum welding wire for MIG and TIG welding of unalloyed aluminum, which provides good color match after anodizing. It is suitable for electric applications. It has highly resistant to chemical corrosion and excellent conductivity. Specialised in the development and production of aluminium and aluminium alloy welding wires

Category: Aluminum Alloy Welding Wire

Aluminum & Aluminum Alloy Welding Wire

IA1050/A1100: Pure aluminum welding wire for MIG and TIG welding of unalloyed aluminum, which provides good color match after anodizing. It is suitable for electric applications. It has highly resistant to chemical corrosion and excellent conductivity.

IA4043: A silion aloyed aluminum welding wire, it is using in welding heat-treatable base alloys and more specifically - the 6XXXX series alloys. It can also be used for joining wrought to cast materials due to its weakly sensitive to heat cracking. Silicon in the wire increases fluidity of mixture, so that is complimentary by operator.

IA4047: A silicon alloyed aluminum wire developed for aluminum brazing with a lower melting point and higher fluidity than IA4043.

It can also be used as a welding fller metal. Also can take the place of IA4043 to increase silicon content in the weld metal, which will minimize hot cracking and strengthen higher fllet weld shear

IA5183: Designed to weld high magnesium alloys to meet higher tensile strength requirement. Used on 5083 and 5654 base materials,when required tensile strengths are 40ksi (276Mpa) or more, typical application is marine and cryogenic industries, and high strength structural aluminum fabrications.

IA5356: Magnesium alloyed aluminum welding wire. A great general purpose fller alloy, designed for the welding of 5XXXX series alloys, when 40ksi(276Mpa) tensile strength is not required. Excellent color matches after anodizing.

Selection guide

| busbar | 319.0 333.0 354.0 355.0 380.0 | 356.0 357.0 359.0 413.0 444.0 443.0 | 511.0 512.0 513.0 514.0 | 7005k 7018 7021 7029 7039 710.0 711.0 712.0 | 6070 | 6061 6063 6062 6101 6201 6151 6351 6051 | 5456 | 5454 | 5154 5254a | 5086 | 5083 | 5052 5652a | 5005 5050 | 3004 | 2219 2519 | 2014 2036 | 1100 3003 | 1060 1070 1080 1350 |

| 1060 1070 1080 1350 | 4145 c,i | 4043 i,f | 5356 c,e,i | 5356 c,e,i | 4043 i | 4043 i | 5056 c | 4043 i | 5356 c,e,i | 5056 c | 5056 c | 4043 i | 1100 c | 4043 | 4145 | 4145 | 1100 c | 1188 i |

| 1100 3003 | 4145 c,i | 4043 i,f | 5356 c,e,i | 5356 c,e,i | 4043 i | 4043 i | 5056 c | 4043 e,i | 5356 c,e,i | 5056 c | 5056 c | 4043 e,,i | 4043 e | 4043 e | 4145 | 4145 | 1100 c | |

| 2014 2036 | 4145 g | 4145 | 4145 | 4145 | 4145 g | 4145 g | ||||||||||||

| 2219 2519 | 4145 g.c,i | 4145 c,i | 4043 i | 4043 i | 4043 f,i | 4043 f,i | 4043 | 4043 i | 4043 i | 4043 | 4043 | 4043 i | 4043 | 4043 | 2319 c,f,i | |||

| 3004 | 4043 i | 4043 i | 5654 b | 5356 e | 4043 e | 4043 b | 5356 e | 5654 b | 5654 b | 5356 e | 5356 e | 4043 e,i | 4043 e | 4043 e | ||||

| 5005 5050 | 4043 i | 4043 i | 5654 b | 5356 e | 4043 e | 4043 e | 5356 e | 5654 b | 5654 b | 5356 e | 5356 e | 4043 e,i | 4043 d,e | |||||

| 5052 5052 | 4043 i | 4043 b,i | 5654 b | 5356 e | 5356 b,c | 5356 b,c | 5356 b | 5654 b | 5654 b | 5356 e | 5356 e | 5356 a,b,c | ||||||

| 5083 | 5356 c,e,i | 5656 e | 5183 e | 5356 e | 5356 e | 5183 e | 5356 e | 5356 e | 5356 e | 5356 e | ||||||||

| 5086 | 5356 c,e,i | 5656 e | 5356 e | 5356 e | 5356 e | 5356 e | 5356 b | 5356 b | 5356 e | |||||||||

| 5154 5254a | 4043 b,i | 5654 b | 5356 b | 5356 b,c | 5356 b,c | 5356 b | 5356 e | 5654 a,b | ||||||||||

| 5454 | 4043 i | 4043 b,i | 5654 b | 5356 b | 5356 b,c | 5356 b,c | 5356 b | 5654 c,e | ||||||||||

| 5456 | 5356 c,e,i | 5656 e | 5356 e | 5356 e | 5356 e | 5356 b | ||||||||||||

| 6061 6063 6082 6101 6201 6151 6351 6951 | 4145 c,.i | 4043 f,I | 5356 b,c | 5356 b,c,I | 4043 b,I | 4043 b,I | ||||||||||||

| 6070 | 4145 c,i | 4043 b,i | 5356 c,e | 5356 c,e,j | 4043 e,i | |||||||||||||

| 7005k 7018 7021 7029 7039 710.0 711.0 712.0 | 4043 I | 4043 b,I | 5356 b | 5356 e | ||||||||||||||

| 511.0 512.0 513.0 514.0 | 4043 b,i | 5654 b,d | ||||||||||||||||

| 356.0 357.0 359.0 413.0 444.0 443.0 | 4145 c,i | 4043 d,i | ||||||||||||||||

| 319.0 333.0 354.0 355.0 380.0 | 4145 d,c,i |

1100 Al99.0Cu

Typical composition%

| Si+Fe | <0.95 |

| Cu | 0.05-0.20 |

| Mn | <0.05 |

| Be | <0.0003 |

| Zn | <0.10 |

| AI | >99.00 |

Weld physical properties(Approx. value)

Rp0.2(Mpa): 80

Rm(Mpa): 130

Elongation Asomm(%): 18

Test temperature(°C): 20

Standard

GB/T 10858-2008: SAI 1100

AWS A5.10-2012: ER 1100

Performance & Usage

This is a kind of pure aluminum welding wire with the aluminum more than 99.0% It has advantages ranges over good anti-corrosiveness, good electrical conductivity and processiveness. And it also is a kind of best choice for color-match after anodic process. Recommended type: aluminum alloy 1XXX.

Product usage: engine, electric power, chemistry, food, etc.

Shielding gas

Argon(99.99),Helium(99.99) or Argon, Helium-mixure(50+50%)

Dimension

MIG-wires(mm) 0.8;0.9; 1.0; 1.2; 1.6; 2.0; 2.4

MIG-rods(mm) 1.6; 2.0; 2.4; 3.2; 4.0; 5.0; 6.0

Packaging

MIG-wires:S100:0.5kg 1LB S200:2kg S300:7kg/9kg 16LB

(TIG-Rods)5/10kg

(L ength): 1000/914mm

4043 AlSi5

Typical composition%

| Si | 4.5-6.0 |

| Fe | <0.80 |

| Cu | <0.30 |

| Mn | <0.05 |

| Mg | <0.05 |

| Zn | <0.10 |

| Be | <0.0003 |

| Ti | <0.20 |

| Other | <0.05 |

| Other total | <0.15 |

Weld physical properties(Approx. value)

Rp0.2(Mpa): 70

Rm(Mpa): 170

Elongation Asomm(%): 10

Test temperature("C): 20

Standard

GB/T 10858-2008: SAI 4043

AWS A5.10-2012: ER 4043

Performance & Usage

This type of pruduct can be used in forging and casting alloys welding due to it has silicon of 5% with thd good performance in anti-thermal crack.

Product usage: ships,engine,chemistry,food,sports,uipment,mould,furniture,vessel,container,etc.

Shielding gas

Argon(99.99),Helium(99.99) or Argon, Helium-mixure(50+50%)

Dimension

MIG-wires(mm) 0.8;0.9; 1.0; 1.2; 1.6; 2.0; 2.4

MIG-rods(mm) 1.6; 2.0; 2.4; 3.2; 4.0; 5.0; 6.0

Packaging

MIG-wires:S100:0.5kg 1LB S200:2kg S300:7kg/9kg 16LB

(TIG-Rods)5/10kg

(L ength): 1000/914mm

4047 AlSi12

Typical composition%

| Si | 11.0-13.0 |

| Fe | <0.80 |

| Cu | <0.30 |

| Mn | <0.05 |

| Mg | <0.10 |

| Ti | <0.15 |

| Zn | <0.20 |

| Be | <0.0003 |

| Other | <0.05 |

| Other total | <0.15 |

Weld physical properties(Approx. value)

Rp0.2(Mpa): 70

Rm(Mpa): 170

Elongation Asomm(%): 9

Test temperature("C): 20

Standard

GB/T 10858-2008: SAI 4047

AWS A5.10-2012: ER 4047

Performance & Usage

This is a type of pruduct which can be applyed in welding all kinds of forging and casting or extruded shape aluminum alloys. And it has advantages of low melting point and good fluidity which avoids the distortion after welding.

Product usage: jointing or overlay light alloy processing.

Shielding gas

Argon(99.99),Helium(99.99) or Argon, Helium-mixure(50+50%)

Dimension

MIG-wires(mm) 0.8;0.9; 1.0; 1.2; 1.6; 2.0; 2.4

MIG-rods(mm) 1.6; 2.0; 2.4; 3.2; 4.0; 5.0; 6.0

Packaging

MIG-wires:S100:0.5kg 1LB S200:2kg S300:7kg/9kg 16LB

(TIG-Rods)5/10kg

(L ength): 1000/914mm

5087 AIMg4.5MnZr

Typical composition%

| Si | <0.25 |

| Fe | <0.40 |

| Cu | <0.05 |

| Mn | 0.7-1.1 |

| Mg | 4.5-5.2 |

| Ti | <0.15 |

| Zr | 0.10-0.20 |

| Zn | <0.25 |

| Be | <0.0003 |

| Cr | 0.05~0.25 |

Weld physical properties(Approx. value)

Rp0.2(Mpa): 125

Rm(Mpa): 290

Elongation Asomm(%): 16

Test temperature("C): 20

Standard

GB/T 10858-2008: SAI 5087

AWS A5.10-2012: ER 55087

Performance & Usage

This is a kind of aluminum-magnesium basis alloys with addition of Zirconium acts as grain-refiner to improve both thebending and the corrosion resistance.Product usage: construction of ships, storage tanks,railways and automotive industry

Shielding gas

Argon(99.99),Helium(99.99) or Argon, Helium-mixure(50+50%)

Dimension

MIG-wires(mm) 0.8;0.9; 1.0; 1.2; 1.6; 2.0; 2.4

MIG-rods(mm) 1.6; 2.0; 2.4; 3.2; 4.0; 5.0; 6.0

Packaging

MIG-wires:S100:0.5kg 1LB S200:2kg S300:7kg/9kg 16LB

(TIG-Rods)5/10kg

(L ength): 1000/914mm

5183 AIMg4.5Mn0.7

Typical composition%

| Si | <0.40 |

| Fe | <0.40 |

| Cu | <0.10 |

| Mn | 0.05-1.0 |

| Mg | 4.3-5.2 |

| Ti | <0.15 |

| Zn | <0.25 |

| Be | <0.0003 |

| Cr | 0.05~0.25 |

| Other | <0.05 |

| Other total | <0.15 |

Weld physical properties(Approx. value)

Rp0.2(Mpa): 120

Rm(Mpa): 285

Elongation Asomm(%): 17

Test temperature("C): 20

Standard

GB/T 10858-2008: SAI 5183

AWS A5.10-2012: ER 5183

Performance & Usage

This is a type of pruduct which can be used in jointing and overlay processing in the same grade of magnesiumof 4.5%, it has good performance in jointing, anti-corrosiveness and mechanics.

Product usage: pressure vessle of chemical industry, nuclear industry, ship-bulding, boiler, space industry, etc.

Shielding gas

Argon(99 99),Helium(99.99) or Argon, Helium-mixure(50+50%)

Dimension

MIG-wires(mm) 0.8;0.9; 1.0; 1.2; 1.6; 2.0; 2.4

MIG-rods(mm) 1.6; 2.0; 2.4; 3.2; 4.0; 5.0; 6.0

Packaging

MIG-wires:S100:0.5kg 1LB S200:2kg S300:7kg/9kg 16LB

(TIG-Rods)5/10kg

(L ength): 1000/914mm

5356 AIMg5.0

Typical composition%

| Si | <0.25 |

| Fe | <0.40 |

| Cu | <0.10 |

| Mn | 0.05-0.20 |

| Mg | 4.5-5.5 |

| Cr | 0.05-0.20 |

| Ti | 0.06-0.20 |

| Zn | <0.10 |

| Be | <0.0003 |

| Other | <0.05 |

|

Other total

|

<0.15 |

Weld physical properties(Approx. value)

Rp0.2(Mpa): 110

Rm(Mpa): 275

Elongation Asomm(%): 17

Test temperature("C): 20

Standard

GB/T 10858-2008: SAI 5356

AWS A5.10-2012: ER 5356

Performance & Usage

This type of pruduct is a widely used in general welding material with the magnesium of 5%,which can be used in jointing or overlay forging and casting alloys processing. This product is of high toughness, good forgeabilit and anti-corrosiveness. Furthermore, this is a good choice for color-match in welding after anodic process.

Product usage: bicycles, aluminum sccoter, etc.engine carriage,pressure vessel, armary processing,ship-building,space shutle etc.

Shielding gas

Argon(99 99),Helium(99.99) or Argon, Helium-mixure(50+50%)

Dimension

MIG-wires(mm) 0.8;0.9; 1.0; 1.2; 1.6; 2.0; 2.4

MIG-rods(mm) 1.6; 2.0; 2.4; 3.2; 4.0; 5.0; 6.0

Packaging

MIG-wires:S100:0.5kg 1LB S200:2kg S300:7kg/9kg 16LB

(TIG-Rods)5/10kg

(L ength): 1000/914mm

Keywords: Aluminum & Aluminum Alloy Welding Wire

Recommended products

Products

Feedback

Online Messages

You can leave us your needs or suggestions online, and we will reply to you as soon as we receive them.

0086 15861898655

0086 15861898655